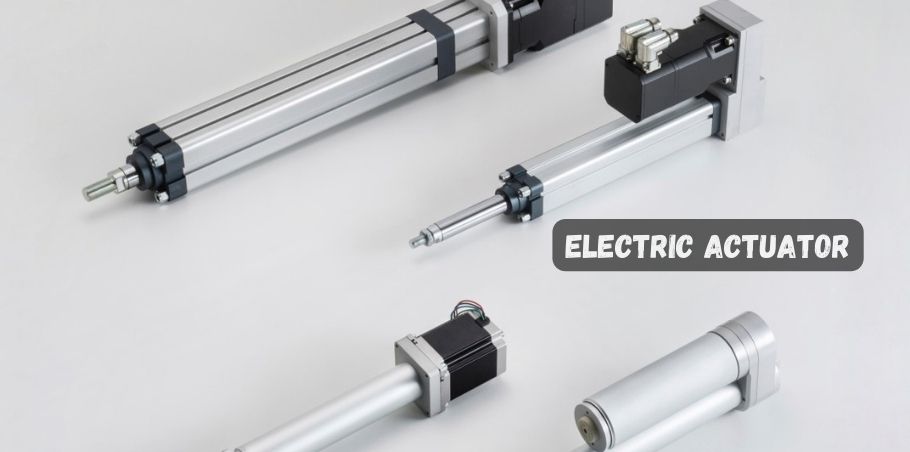

Electric actuator: Driving the Next Generation of Automated Solutions

In the world of automated systems and advanced machinery, electric actuators stand out as essential components that drive modern innovation. Acting as the “muscles” of machinery, these devices enable precise movement and control across countless industries—from robotics and manufacturing to consumer electronics and healthcare.

What Are Electric Actuators?

Electric actuators are devices that convert electrical energy into mechanical motion. This movement can be linear, rotational, or a combination, depending on the type of actuator. At their core, actuators electric consist of several key components: motors, gears, sensors, and control systems that coordinate the movement and ensure precise operation.

Types of Electric Actuators

Following are the types of electric actuators

Linear actuators electric

Linear actuators electric convert electrical energy into straight-line (linear) motion. They are commonly used for applications that require lifting, sliding, or pulling.

Rotary Electric Actuators

These actuators convert electrical energy into rotational motion, making them ideal for applications like robotic arms and rotating machinery parts.

Specialty Actuators for Unique Applications

In addition to standard types, there are specialty actuators designed for specific applications, such as high-torque environments or small-scale, precision-driven devices.

How actuators electric Work

The basic working principle of an actuators electric involves converting electrical energy into mechanical energy. The motor initiates this energy transfer, which is then amplified by gears and transmitted to a moving component. This conversion allows the actuator to perform functions such as lifting, rotating, or positioning.

12V Linear Actuator

A 12V linear actuator is a compact and versatile device that converts electrical energy into linear motion, making it ideal for a wide range of applications. Operating at a low voltage, this actuator is commonly used in scenarios where safety and energy efficiency are paramount, such as in home automation systems, medical devices, and automotive applications. The 12V power supply allows for easy integration with standard battery systems, making these actuators particularly popular for DIY projects and robotics. With various stroke lengths and load capacities available, 12V linear actuators offer flexibility for tasks such as lifting, pushing, or pulling heavy objects with precision.

Advantages of actuators electric Over Other Actuators

Actuators electric offer numerous advantages over hydraulic and pneumatic actuators:

-

Efficiency and Precision

Actuators electric allow for highly controlled and precise movement, making them suitable for applications requiring exact positioning.

-

Control and Automation Capabilities

With advanced control systems, actuators electric integrate seamlessly into automated systems.

-

Environmental Benefits:

Electric actuators don’t require fluids, reducing the risk of contamination and making them more environmentally friendly.

Applications of Electric Actuators

Actuators electric are used across various industries due to their reliability and versatility.

Industrial Automation

In automated factories, actuators electric play a crucial role in moving parts along assembly lines and positioning equipment.

Robotics

Robotic systems rely on actuators electric for controlled, precise motion, such as in robotic arms that handle materials and perform tasks like welding.

Automotive Industry

Actuators electric are common in vehicles for controlling seats, mirrors, and other parts, enhancing comfort and safety.

Healthcare and Medical Devices

From hospital beds to surgical robots, actuators electric are key to ensuring precise control in critical healthcare applications.

Consumer Electronics

Electric actuators are used in adjustable parts of electronic devices, such as motorized mounts for screens.

Components of Electric Actuators

Here are the components of actuators electric

Motors

The motor is the heart of an actuators electric , converting electrical energy into mechanical motion.

Gears

Gears within the actuator amplify force and control speed, allowing for both fine and high-torque adjustments.

Sensors

Sensors provide feedback, enabling precise control of movement and positioning.

Controllers

Controllers act as the “brain,” managing and coordinating the entire actuator system for smooth operation.

Throttle actuator assembly for an electric boat

The throttle actuator assembly for an electric boat plays a crucial role in managing the vessel’s speed and performance. This system converts electrical signals from the control interface into precise mechanical movements that adjust the throttle position. By ensuring smooth acceleration and deceleration, it enhances the overall boating experience while promoting energy efficiency. The assembly typically includes components such as an electric motor, gears, and position sensors, all designed to withstand the marine environment. As electric boats become increasingly popular, optimizing the throttle actuator assembly is essential for achieving responsive handling and maximizing battery life. Ultimately, this innovation represents a significant advancement in electric boating technology, offering a seamless blend of power and control on the water.

Throttle actuator assembly for an electric boat rv4daysd602a

The throttle actuator assembly for the electric boat RV4DAYS-D602A is a critical component that ensures optimal performance and efficiency. This assembly is responsible for precisely controlling the throttle position, which directly affects the speed and responsiveness of the vessel. Designed for durability and reliability, it seamlessly integrates with the boat’s electrical system to provide smooth operation. The actuator responds quickly to user input, allowing for fine-tuned adjustments while navigating through various water conditions. Its compact design is engineered to fit within the limited space of an electric boat without compromising performance. Overall, the throttle actuator assembly is essential for enhancing the boating experience, ensuring that every journey is both enjoyable and efficient.

Electric Actuators vs. Hydraulic and Pneumatic Actuators

While actuators electric offer many benefits, hydraulic and pneumatic actuators have their own advantages in specific applications.

-

Hydraulic Actuators:

Provide greater force and are suitable for heavy-duty applications but require fluid maintenance.

-

Pneumatic Actuators:

Use compressed air and are often faster, but they lack the precision and energy efficiency of actuators electric .

Materials Used in Electric Actuators

Actuators electric actuators electric are constructed using a combination of metals, alloys, and polymers chosen for their durability, strength, and resistance to wear. These materials contribute to the longevity and reliability of the actuators.

Selecting the Right Electric Actuator

When choosing an actuators electric , consider factors such as required force, speed, accuracy, and compatibility with other systems. Matching these requirements to the actuator’s specifications ensures optimal performance.

Installation and Maintenance of Electric Actuators

Proper installation and regular maintenance are crucial for maximizing the lifespan of an actuators electric .

-

Installation Tips:

Follow manufacturer instructions and ensure compatibility with other components.

-

Maintenance Tips:

Regularly inspect for wear and lubricate parts as needed.

-

Troubleshooting:

Common issues include misalignment and overheating; addressing these quickly prevents further damage.

The Future of Electric Actuators

Advances in artificial intelligence (AI) and the Internet of Things (IoT) are shaping the future of actuators electric . These technologies allow actuators to learn and adapt, further increasing their precision and reliability.

Environmental Impact and Sustainability

Actuators electric are generally more energy-efficient than hydraulic and pneumatic options. They play a significant role in green technologies, including solar panel tracking and electric vehicles.

Case Studies: Real-World Examples

Real world examples of electric actuator

Electric Actuators in Robotics

Actuators electric are pivotal in developing robotic arms that can perform highly precise tasks, such as surgery or assembly.

Automation in Manufacturing Plants

Automated assembly lines use actuators electric for moving components with accuracy and speed, contributing to high productivity and quality.

FAQs About electric actuator

What is the primary benefit of electric actuators over hydraulic actuators?

It offer greater precision and control without the need for fluid maintenance, making them ideal for clean, precise applications.

Can electric actuators be used in outdoor applications?

Yes, many actuators electric are designed for outdoor use, with weather-resistant materials and coatings to handle harsh conditions.

How do I maintain an electric actuator?

Regularly inspect for signs of wear, lubricate moving parts as specified by the manufacturer, and check for alignment to ensure optimal performance.

What is the lifespan of a typical actuators electric ?

Lifespan varies by type and usage, but with proper maintenance, actuators electric can last several years, sometimes even decades.

Are electric actuators eco-friendly?

Yes, actuators electric are generally more eco-friendly than hydraulic and pneumatic actuators, as they don’t require fluids and are more energy-efficient.

Conclusion

Electric actuators are foundational to modern automation, offering precision, efficiency, and environmental benefits that set them apart from other types of actuators. With advances in technology, their potential continues to grow, making them indispensable for industries that require precise motion control.

If you gained new insights from this article, explore our blog, Gimkit, for more enlightening content.

Share this content:

Post Comment